In its latest interview for the May/June issue, Drilling Contractor’s Stephen Whitfield interviewed two members of the Knowledge Retention & Education for our Workforce (KREW) Steering Panel: Mike Garvin, Senior VP Operations at Patterson-UTI, and Jeremy Sokol, Technical Training Unit Manager at Chevron.

DRILLBITS

Monthly eNewsletter from the IADC

Industry Experts Make Case for Evolving Well Control Training

As members of the KREW Steering Panel as well as IADC’s WellSharp Advisory Panel, they have been a involved in various well control initiatives over the past several years including the design, development, and deployment of both WellSharp and KREW. Most recently, as a result of the COVID-19 pandemic last year, arose the urgent need for a remote-learning platform in WellSharp Live – a rapid development no one in the industry saw coming. Leveraging the groundwork laid by KREW, the WellSharp Advisory Panel quickly approved the platform for online delivery of well control training.

Innovating Well Drilling Means Innovating Well Control Training

Ever since the transition of WellCAP to WellSharp four years ago, the WellSharp Advisory Panel has known that continuous education would be an important component to well control training, as ever evolving innovations were pushing other parts of the industry to change how they operated.

Mike Garvin, in his interview with Stephen Whitfield:

I believe the fundamental issue is the drilling practices have evolved over time, particularly over the last few years, and well control training has just not kept pace with these evolutions, nor is it structured to keep pace in the future.

He later explains that KREW enables companies to structure training to provide reminders and refreshment of key concepts. He is an advocate of this type of approach instead of requiring employees to repeat the entire 4-5 days of well control training all over again every two years.

The panel is addressing both immediate needs as well as looking to the future of well control training in our industry. That’s why the Panel is made up of a wide representation of companies:

- BP

- Chevron

- Endeavor Energy Resources

- Ensign

- Helmerich & Payne

- Noble Drilling

- Patterson UTI

- Precision Drilling

- Shell

- Valaris Drilling

Solving Knowledge Loss

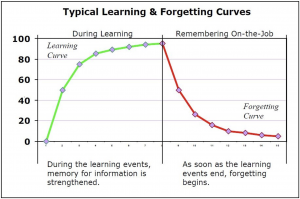

While everyone has heard about “The Learning Curve,” its natural counterpart —”The Forgetting Curve”—is not necessarily as widespread outside of academia. Not everyone forgets the same information at the same time, which means the specific solution cannot have a one-size-fits-all approach.

The digitization of delivering well control training via WellSharp Live provides the industry the opportunity to create a seamless transition between the initial well control training and the continuous-learning necessary to improve safety training.

The digitization of delivering well control training via WellSharp Live provides the industry the opportunity to create a seamless transition between the initial well control training and the continuous-learning necessary to improve safety training.

In the interview, Mr. Sokol underlines the how WellSharp Live is helped by KREW:

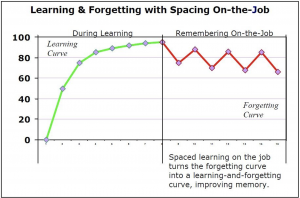

“KREW focuses on the continuing learning aspect with the ultimate goal of improving safety during all of our oil and gas operations. The structure, tracking and flexibility built into KREW provides users opportunities to minimize that forgetting curve.”

With substantial academic research about how adults learn, forget, and recall their technical knowledge, KREW addresses the skills gap measured both inside and outside the drilling industry.

Working within a two-year cycle between well control certifications, the model can be improved by re-envisioning how well control training is executed in our industry. The issue has mostly been phasing in a different model into the current training cycle.

Working within a two-year cycle between well control certifications, the model can be improved by re-envisioning how well control training is executed in our industry. The issue has mostly been phasing in a different model into the current training cycle.

As the concepts in well control training are not immediately utilized on the jobsite after leaving an educational environment, a trainee isn’t reinforcing the new neural pathways created during recertification training.

Reinforcing What We’ve Learned

Reinforcing previous well control training can be achieved by focusing on the key components of knowledge retention:

- Effective initial learning

- Structured continuous learning

- Application of the learning

Recent changes to the newly created WellSharp Live create the fertile ground for this phased-in approach.

Brooke Polk, IADC’s Senior Director-Accreditation Operations shared,

“Virtual instruction is a delivery method the industry has embraced. We are leveraging the latest technology to help ensure course integrity and assessment security. These types of enhancements allow virtual instruction to remain an accepted delivery method for well control training.”

Also effective 1 May, WellSharp Live Driller and Supervisor level course will automatically provide access to the KREW system.

Combining KREW + WellSharp Live

Effective well control starts with the ability to effectively operationalize the industry’s expertise.

For training to provide long-term value to the industry, the training model has to be re-envisioned. It was decided that a phased-in approach allows IADC to be more agile with any modifications needed and allows time to review analytics to make data-driven decisions to revolutionize the way we train in our industry.

The combination of KREW with WellSharp Live bundles & streamlines the two-year gap between well control certifications by ensuring that critical well control concepts are revisited and reinforced.

Looking beyond sole use for the pandemic, there are enhancements that industry wanted to see incorporated. The additional enhancements for the permanent delivery option has created additional costs for WellSharp Live. These new security enhancements will include eye movement monitoring, screen-locking features, restricted website and computer program access. Security measures like these lay the groundwork for continuous-learning of critical well control concepts.

The incorporation of KREW into WellSharp Live is the first phase of revolutionizing well control training. This gradual shift to a more effective way to train people that targets the knowledge gaps that they have individually. It also provides the ability to target industry-wide gaps and address the needs of a changing industry with consistent targeted training that can be utilized around the world.