The IADC Advanced Rig Technology (ART) Committee is seeking volunteers to join a workgroup to revamp the current IADC dull-bit grading system.

The current system, with the 1 to 8 wear ranking, has been in use, with modifications, since the early 1960s. The system has proved useful, but there is a growing consensus that there is a need to devise a more sophisticated, less subjective procedure.

One of the main drivers is to formulate a method to forensically study the wear characteristics and relate those characteristics to drilling events, which we now have the capability to identify through recent drilling-data capture technologies. The detection of drilling events and their influence on the dull condition of the drill bit will enable the adoption of event mitigation procedures, which will extend the running life of the bit.

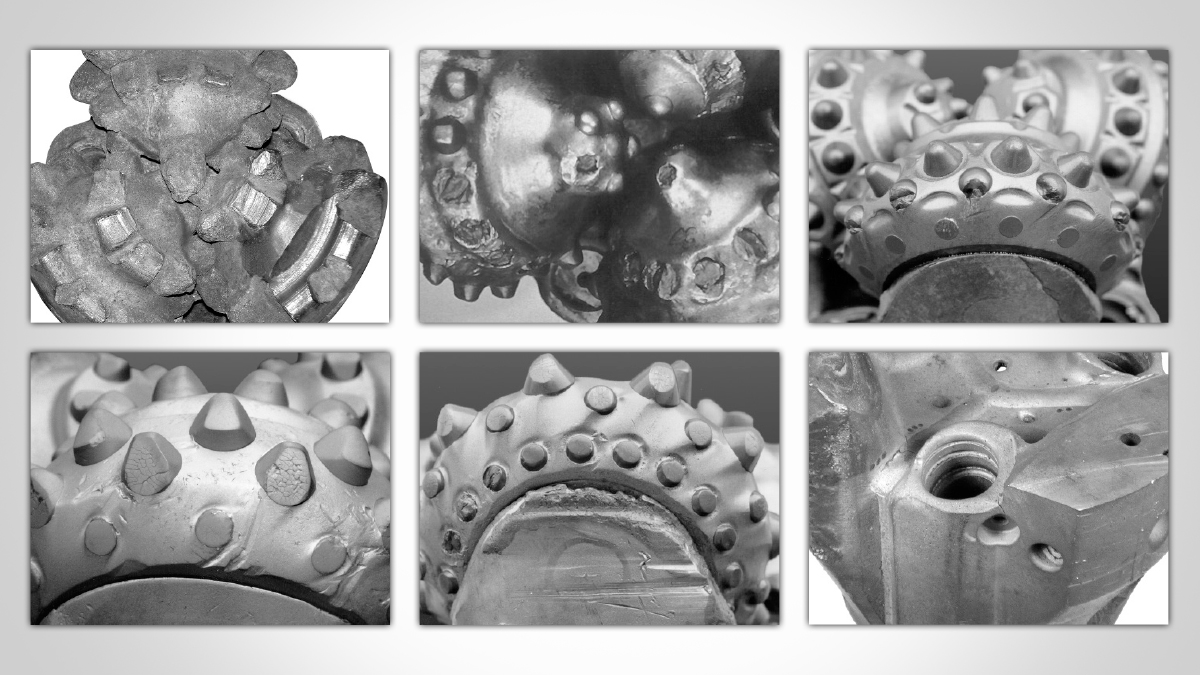

Several methods of capturing drill bit images facilitating the forensic study have already been devised. These include the use of high-definition, multi-image photography and laser technology, some of which, it is proposed, will use facial-recognition type systems to identify detailed wear and damage features.

Systems for capturing the data exist. Systems for applying the data exist. The industry currently lacks a sophisticated system between these two processes for describing the dull characteristics observed, so that it can be properly archived in a data vault for current and future analysis.

The goal is to provide an industry consensus on how we describe a dull bit that will take full advantage of the technologies now available to capture dull-bit images and interpret the reasons for the features identified.

If you would like to join this workgroup or be added to the project mailing list for more information, please send an email to Linda Hsieh at linda.hsieh@iadc.org.